Foam, Microfiber & Wool Buffing Pads

The Key to a Perfect Finish: Professional Foam Polishing Pads

Autogeek's Detailing Secret: It’s All About the Pad

Since 2001, Autogeek has been at the heart of the detailing world, a trusted source for car enthusiasts who demand perfection. We've taught a generation of detailers that while a great polisher is crucial, the real magic happens at the interface between the machine and the paint: the foam polishing pad. This unassuming disc is the most critical variable in the paint correction process, determining how aggressively you correct defects and how brilliantly you finish the surface. Our selection of foam polishing pads is a culmination of decades of hands-on expertise, rigorously tested to ensure you have the right pad for every job. When you shop for pads at Autogeek, you're not just buying a piece of wool or foam—you’re getting the peace of mind that comes with using a product backed by a legacy of quality and trust.

The Science of Foam: Matching Pad to Purpose

Choosing the right pad is a fundamental skill in detailing, as each pad is engineered with a specific density and cell structure to achieve a different result. Using the wrong pad can lead to poor results, or even worse, damaged paint. To help you navigate our extensive selection, we've broken down our pads into three primary categories:

- Cutting Pads: These are your workhorses for paint correction. Made from dense, firm foam, cutting pads are designed to be used with aggressive compounds to remove moderate to heavy paint defects like deep swirl marks, oxidation, and scratches. The firm structure of the foam provides the necessary pressure and cutting action to level the clear coat, preparing the surface for the next step.

- Polishing Pads: These versatile pads are your go-to for a wide range of tasks. With a softer, more flexible foam density, they are perfect for use with medium-cut or fine-cut polishes. Polishing pads are ideal for removing light swirl marks, refining the finish after a compounding step, and restoring clarity and gloss to dull paint.

- Finishing Pads: When you're ready to lay down that perfect, jewel-like finish, a finishing pad is what you need. These pads are made from the softest, most pliable foam to create a flawless, ultra-smooth surface. They are typically used with a finishing polish or a pure wax/sealant to maximize gloss and ensure a streak-free final look. A finishing pad has minimal cutting ability, making it the safest option for the final step.

Pad Technology and Application: Maximizing Your Results

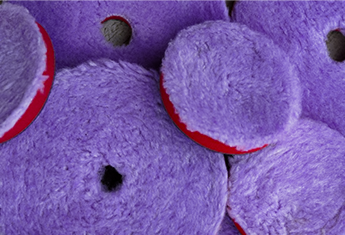

Modern foam pad technology has advanced significantly, offering features that improve performance and longevity. Many of our pads feature a tapered edge for safe polishing around curves and an integrated backing that prevents delamination. We also offer pads with a center hole to help dissipate heat, which is crucial during extended polishing sessions. Whether you're using a dual-action (DA) polisher or a rotary buffer, our pads are designed to work with your machine to deliver consistent, outstanding results.

For best practices, always start with a clean pad and apply only a small amount of product. When working with a DA polisher, apply medium pressure on a low to medium speed and work in a small, 2x2 foot section at a time. This ensures the product is fully worked into the paint and the pad is performing at its best.

Protect Your Investment and Your Finish

Your foam pads are an investment, and proper care is essential to get the most out of them. A dirty pad can ruin a detailing job, reintroducing contaminants and causing new scratches. That’s why we also offer a full line of pad cleaners and brushes designed to quickly and effectively clean your pads after every use. By cleaning and maintaining your pads, you not only extend their life but also ensure that every detail you perform is a success. Trust Autogeek for the tools, the knowledge, and the passion to make your vehicle shine like new.

Shop Similar Products & Videos

Recommended Products from Autogeek.com:

- SONAX Red Cutting Pads

- Lake Country 5.5" CCS Pads

- Buff and Shine EdgeGuard Pads

- Wolfgang Pad Cleaner

How-to Videos on Autogeek’s YouTube Channel:

Frequently Asked Questions (FAQ)

Q: Do I need different pads for different products? A: Yes, absolutely. The general rule is to use different pads for different stages of detailing. Use a cutting pad for a compound, a polishing pad for a polish, and a finishing pad for a finishing polish, wax, or sealant. This prevents cross-contamination and ensures each product works as intended.

Q: How do I know if I'm using the right pad? A: A good sign is when you're achieving the desired result (e.g., removing a scratch) without leaving behind new swirls or haze. If your pad isn't correcting the defect, you may need a more aggressive pad and compound combination. If you’re leaving a haze, you may need to step down to a softer pad and a finer polish. Pro Tip: SONAX color codes their bottle labels for the appropriate pad (green label = green pad)

Q: Can I wash my foam pads? A: Yes, foam pads can and should be washed after every use. You can use a dedicated pad cleaner or a mild degreaser with a soft brush and warm water. Make sure to rinse the pad thoroughly and allow it to air dry completely before using it again.

Q: What is the difference between open-cell and closed-cell foam? A: Open-cell foam is more porous and breathable, which helps to dissipate heat and absorb excess product. It is often used for finishing pads. Closed-cell foam is denser and more rigid, which gives it more cutting power, making it ideal for cutting and polishing pads.